Recognizing the Role of Temperature and Stress Reducers in Industrial Safety

Intro: Temperature and pressure reducers from trusted distributors make certain stable procedure, avoiding failings and protecting possessions across changing industrial problems.

As periods change and commercial demands rise and fall, centers face the challenge of preserving stable operating conditions regardless of variable exterior and interior elements. In the heart of numerous manufacturing plants, equipment silently fights extremes of temperature and pressure that intimidate safety and performance. This is where the experience of a temperature level valve distributor becomes critical. By incorporating temperature and stress reducers, markets not just protect against system failings but likewise shield employees and possessions. For business sourcing from a trustworthy shutoff factory, such as those supplying wholesale temperature shutoff options, these parts end up being essential tools in safeguarding procedures.

Just how stress reducers protect against system overpressure and failures

Pressure reducers play an important duty in preserving devices longevity and operational safety and security by making sure system stress remains within assigned limits. When fluid or gas stress rise unexpectedly due to process adjustments or breakdowns, overpressure can cause valve ruptures, pipe leakages, or complete system shutdowns, bring about costly downtime and hazards. A wholesale shutoff supplier understands the significance of delivering gadgets designed for precision and dependability. By moderating the stress, these reducers maintain a consistent flow and safeguard delicate parts downstream. Control valve vendors usually work together very closely with valve manufacturing facilities to create pressure reducers that can handle diverse commercial fluids while enduring rough conditions, varying from severe temperatures to harsh atmospheres. Choosing the appropriate pressure reducer from a trusted temperature shutoff supplier assists sectors prevent safety and security violations and expands the lifespan of crucial equipment by stopping exhaustion and mechanical tension that emerge from unpredictable pressure spikes.

Temperature shutoffs ensuring risk-free operating problems under variable tons

Variable loads in commercial systems often cause temperature changes that can badly influence procedures and devices safety and security. The visibility of a dependable temperature shutoff, sourced from a specialized wholesale temperature shutoff service provider, makes sure secure thermal control even when outside conditions or operational needs alter swiftly. ball valve manufacturer by instantly readjusting circulation rates, permitting systems to preserve temperature levels within secure limitations. The layout complexities found in shutoffs from a respectable valve manufacturing facility integrate top quality products and specific devices, allowing fast actions to thermal changes without sacrificing control or safety. A control valve vendor committed to development and sturdiness makes certain that temperature valves can withstand constant cycling and high-pressure atmospheres, which prevail in production, chemical handling, and power sectors. This interest to detail dramatically minimizes dangers connected with overheating or freezing, protecting both workers and crucial devices. With regular temperature law, industries reduce dangers of thermal development damages and keep efficient power usage, sustaining more secure and much more sustainable procedures.

Instance instances demonstrating threat mitigation with combined reducers

Incorporating temperature level and pressure reducers into industrial systems uses thorough protection that couple of standalone components can match. For instance, in a chemical handling plant, failing to control both temperature level and stress simultaneously as soon as caused a hazardous release incident. After taking on mixed reducers supplied by an acknowledged temperature level valve distributor and wholesale shutoff supplier, the center reported improved functional security. The dual-function system avoided stress build-ups throughout exothermic responses while keeping secure temperature ranges, substantially mitigating risk factors. Likewise, a power generation site leveraged controls sourced from a very related to valve manufacturing facility to manage steam stress and temperature level in turbines. These shutoffs, made sure by trusted control valve suppliers, offered reputable feedback and change capacities that safeguarded equipment from thermal stress and overpressure-induced wear. Such real-world instances underline how the thoughtful consolidation of well-engineered temperature valves and stress reducers, specifically through reputable wholesale temperature level valve and shutoff factory partnerships, can change security protocols and improve system resilience across diverse industrial environments.

Preserving control over temperature and pressure is vital for operational security and effectiveness, and temperature level and pressure reducers play a crucial duty in this balance. By picking heater control valve from a skilled temperature level valve provider and wholesale temperature valve companies, markets acquire accessibility to robust remedies created within trustworthy shutoff factories. Their styles, incorporating sturdiness and responsiveness, foster self-confidence in systems' capability to withstand ever-changing conditions without threat. With noise integration of these tools from respectable control shutoff distributors, firms considerably lower the unpredictability of mechanical failing or safety and security cases, making certain long-term stability and protection of personnel and assets alike.

Referrals

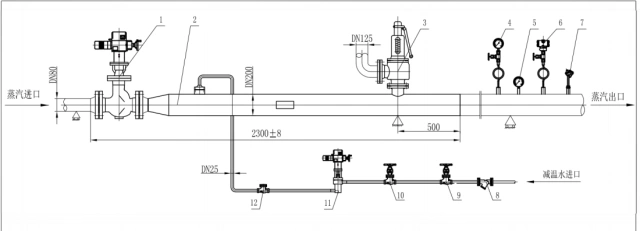

1. Temperature and Pressure Reducer (System Product)-- Thorough service for handling temperature level and stress in commercial systems

2. Controling Valve-- Accuracy control of fluid circulation, pressure, and temperature in pipelines

3. Safety Valve-- Automatic pressure alleviation to avoid overpressure incidents in devices and pipes

4. Refine Security Beacon: Thermal Expansion Runs Hot and Cold-- Insights into managing thermal development to stop equipment failure

5. Pressure Measurements for Dependability, Safety And Security, and Cybersecurity-- Relevance of accurate pressure dimensions in guaranteeing system safety and integrity