Technical Viewpoints on Pressure Reducers within Valve Assemblies

Intro: Stress reducers in shutoff assemblies guarantee risk-free downstream stress regardless of changes, incorporating with temperature control for trustworthy seasonal commercial operation.

As winter season techniques, plants encounter changing needs on their valve systems to keep consistent efficiency under altering environmental problems. This seasonal relevance spotlights stress reducers integrated into shutoff assemblies that change to temperature level variations efficiently. For markets relying on smooth thermal and stress control, sourcing elements from a temperature level valve provider makes sure compatibility and integrity. Operating problems that differ with seasons require robust systems, usually provided by a respectable valve manufacturing facility, making the option of wholesale valve and wholesale temperature level shutoff service providers an essential factor to consider for continual operational quality in cooler months.

Functionality differences between pressure reducers and temperature level control shutoffs

Pressure reducers and temperature control shutoffs clearly support group stability, yet their functional concentrates differ considerably. Stress reducers mainly manage fluid stress, keeping safe downstream conditions no matter rising and fall upstream pressures. In contrast, temperature level control shutoffs manage thermal inputs based on temperature setpoints to secure equipment and improve procedure performance. A control valve supplier often deals with these differences by using tailored remedies depending on the details application needs. While pressure reducers preserve critical system security margins, temperature shutoffs ensure warmth is regulated specifically, mitigating dangers of over-temperature that might jeopardize performance. From a shutoff factory viewpoint, making and producing parts that succeed in either stress or temperature level control involves picking products and devices that respond properly to their targeted parameter. The wholesale temperature shutoff products emphasize responsiveness to thermal variations, whereas wholesale shutoff items focusing on stress reducers concentrate on toughness and stress durability. Recognizing these practical distinctions helps commercial users source the appropriate devices for optimized general valve assembly efficiency, leveraging experience from specialized suppliers for temperature shutoffs or stress reducers.

Selecting appropriate systems for mixed temperature level and stress policy

Many commercial processes require incorporated law systems that all at once attend to temperature level and stress variables for structured control and safety. For such mixed needs, sourcing from a temperature level valve provider with the ability of supplying wholesale temperature shutoff settings up that include stress minimizing functions becomes essential. toilet shut off valve manufacturing facilities catering to these needs designer modular or system items that link temperature level and stress control, lowering intricacy and points of failing in shutoff settings up. Selecting ball valve manufacturer made for dual regulation calls for looking at just how control shutoffs interface within the assembly, ensuring responsiveness does not experience due to multifunction demands. Wholesale shutoff choices that merge functions streamline installation and upkeep, providing cohesive procedure in challenging process settings. Having a control valve supplier able to give functional services increases the probability of compatibility with existing framework while meeting strenuous commercial criteria. These systems commonly symbolize innovative sensing and regulating components efficient in adapting to rising and fall tons, making certain temperature level and pressure remain within ideal limits. Industrial users that represent these considerations when involving with shutoff factories and wholesale providers stand to take advantage of improved system reliability and operational long life.

Quality assurance processes making certain valve item dependability

Ensuring reliability throughout pressure reducers and temperature control valves begins with stringent quality assurance methods at the valve manufacturing facility phase. A temperature level valve supplier devoted to strict testing and conformity structures ensures that wholesale temperature shutoff products fulfill exact efficiency criteria defined by industry policies. These procedures consist of product traceability, mechanical endurance screening, and calibration precision evaluations to validate control valves operate consistently under varied operating conditions. Wholesale shutoff manufacturing that sticks to recorded quality control measures reduces risks related to premature failures or improper part actions in high-stakes industrial applications. Control shutoff suppliers usually execute both standardized and customized quality assurance tailored to the operational setting of the intended product. Such diligence promotes certain combination into shutoff assemblies, enabling end individuals to depend on sustained accuracy and durability. Beyond first manufacturing, recurring monitoring of valve performance through robust comments systems even more safeguards long-lasting reliability. Choosing valve items from factories with mature quality assurance procedures converts right into fewer interruptions and upkeep needs, highlighting the important duty of provider know-how in commercial valve system success.

As industries adjust to seasonal changes and complex functional needs, engaging with a trusted temperature level shutoff supplier guarantees access to reputable valve manufacturing facility services. Whether concentrating on standalone stress reducers or integrated assemblies offering temperature level and pressure policy, the best wholesale shutoff products provide safe, precise control essential for secure processes. The thoughtful layout and strenuous quality assurance installed in these systems offer regular convenience and efficiency in application. Looking ahead, the synergy between advanced valve innovations and dependable suppliers will certainly proceed sustaining developing industrial settings where flexibility and accuracy remain paramount.

Referrals

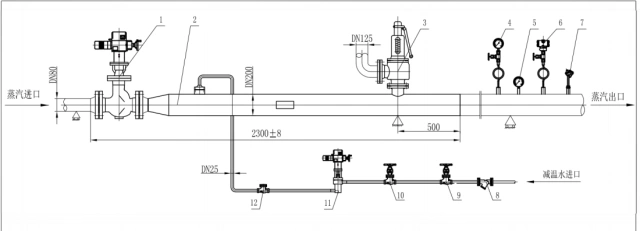

1. Temperature and Stress Reducer (System Product)-- Integrated system for handling both temperature level and pressure in commercial applications.

2. Controling Valve-- Controls liquid flow, pressure, and temperature level with high precision for industrial procedures.

3. Safety And Security Shutoff-- Automatically discharges excess stress to protect tools like boilers and stress vessels.

4. Latest Technologies in Stress Reducing Regulator Technology-- Explores modern products and accuracy production improving PRV efficiency.